Shaft Alignment

Shaft Alignment

Shaft alignment, sometimes also known as “coupling alignment”, is the process of making two or more rotating shafts collinear, or aligned in a single straight line, both horizontally and vertically. Most rotating machinery are often susceptible to misalignment. Shaft misalignment affects the life cycle of machinery critically.

A misaligned shaft results in the following: Increased friction and therefore also increased energy consumption; excessive and unnecessary vibration and noise; premature bearing and seal failure; seal and lubricant leakage; and finally, premature shaft and coupling failure.

Fact: Studies have shown that shaft misalignment causes up to 50% of all rotating machinery breakdowns.

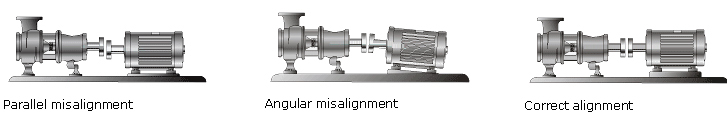

There are two types of misalignment: Angular and Parallel misalignment:

In Angular misalignment, the centerlines of both shafts lie at an angle to each other instead of being parallel.

In Parallel misalignment, both the shaft centerlines are parallel, but they are offset by a distance

Advantage of Shaft Alignment :

Advantage of Shaft Alignment :

- Reduces power consumption

- Increases bearing service life

- Improves shaft and machine performance

- Reduces stress on bearings, shafts, couplings and seals.

- Avoids overheating of bearings and couplings

- Reduces vibrations and noise

- Increases production capacity and quality

- Prolongs the total service life cycle of machine.

Prolongs the total service life cycle of machine.

Shaft alignment can be done through a variety of methods and instruments, such as straight edges, callipers, dial indicators or laser systems.

Laser shaft alignment is the fastest and most accurate method of shaft alignment.

Why Choose MIMS ?

Why Choose MIMS ?

MIMS specializes in providing fully integrated solutions and specially tailored services for laser alignment. With our vast experience, extensive network and technical expertise, our in-house engineering team is able to respond quickly and effectively to even your most critical operational needs. Our team of experts can have your equipment operational in the shortest possible time, thus minimalizing operating losses through production downtime.

For more information, please Click here to contact us.